Innovative stainless steel machines for most efficient oil seperation

The innovative oil separator is made of stainless steel and includes a four-chamber labyrinth system, which efficiently enables the separation of oils.

CLICK ON THE CATEGORIES AND READ MORE

Compact, powerfull and effective magnetic solution

Easy to integrate into existing equipment and is mainly used for mounting on a band filter. This magnetic separator comes with a very powerful magnet and a large surface area, which makes it extremely effective in removing magnetic particles.

CLICK ON THE CATEGORIES AND READ MORE

Innovative, compact and high quality developed central systems

Reduce your operating costs significantly, extend the life of your tools and protect the environment with a central filtration system from us.

CLICK ON THE CATEGORIES AND READ MORE

Wide range of high quality, compact and efficient lubricant filtering solutions

The well-designed filtration system will remove dirt and residue, and reduce your operating costs significantly. Extend the life of your tools and protect the environment now!

CLICK ON THE CATEGORIES AND READ MORE

Additional powerful and compact filtering accessories

Filco industry machine connections are the most gentle to fluids on the market.

CLICK ON THE CATEGORIES AND READ MORE

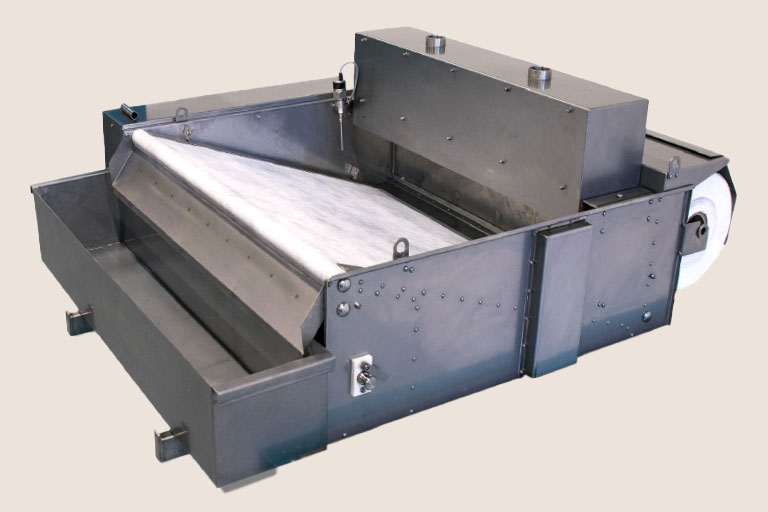

Band Filter UF

Our high quality band filters are produced in stainless steel. They are mainly used for filtration of coolants, oils and process fluids from cleaning systems and CNC-machines.

The band filters are produced in different sizes depending on customer needs and can filtrate up to 600 liters per minute. The band filters uses filter paper which can be acquired in different types depending on the application. The band filters can be used separately as stand-alone-units or as a build-in unit for larger filtration systems.

Applications:

- Coolant

- Process fluid

- Oil

- Water treatment

- Sewage

Extra options:

- Filter paper up to Ø290 mm

- Stainless steel support frame

- Polypropylene and stainless steel containers

- Tank unit

- Construction in AISI 316 / EN 1.4401

FEATURES

100% stainless steel construction

Produced in AISI 304 / EN 1.4301.

Frequency regulated

The frequency regulated gear motor enables a smooth and slow movement of the of the filter paper, which ensures the permanent build-up of a filter cake.

Analog control cabinet

The band filter has a control cabinet with lamps to provide information about filter paper status and alarm status.

Level sensor

The digital level sensor ensures precise use of filter paper. This also makes the filter very efficient because of the continuously high fluid pressure. This reduces operation costs and results in better filtration.

Paper sensors

The band filter has built-in sensors for low paper and full paper.

Overflow surveillance

The band filter has build-in overflow surveillance. In case of overflow the bypass duct ensures that the fluid is lead through the filter instead of overflowing the filter.

CE - EU Machinery Directive

The band filter is produced in Denmark in conformity with the EU Machinery Directive.

TECHNICAL DATA

| Model | UF 250 | UF 500 | UF 700 | UF 1000 | UF 2000 |

|---|---|---|---|---|---|

| Length | 965 mm | 965 mm | 965 mm | 965 mm | 965 mm |

| Width | 450 mm | 700 mm | 900 mm | 1200 mm | 1200 mm |

| Inlet height | 538 mm | 538 mm | 538 mm | 538 mm | 657 mm |

| 1 1/2″ inlet | 1 pcs. | 2 pcs. (200 mm C-C) | 2 pcs. (300 mm C-C) | 2 pcs. (400 mm C-C) | 2 pcs. (400 mm C-C) |

| Flow capactiy | 100 L/min | 150 L/min | 250 L/min | 350 L/min | 600 L/mm |

| Power supply | 1x230V / 3x400V + N + PE – 50 Hz | 1x230V / 3x400V + N + PE – 50 Hz | 1x230V / 3x400V + N + PE – 50 Hz | 1x230V / 3x400V + N + PE – 50 Hz | 1x230V / 3x400V + N + PE – 50 Hz |

| Control current | 24 VDC | 24 VDC | 24 VDC | 24 VDC | 24 VDC |

| Protection grade | IP54 | IP54 | IP54 | IP54 | IP54 |