Innovative stainless steel machines for most efficient oil seperation

The innovative oil separator is made of stainless steel and includes a four-chamber labyrinth system, which efficiently enables the separation of oils.

CLICK ON THE CATEGORIES AND READ MORE

Compact, powerfull and effective magnetic solution

Easy to integrate into existing equipment and is mainly used for mounting on a band filter. This magnetic separator comes with a very powerful magnet and a large surface area, which makes it extremely effective in removing magnetic particles.

CLICK ON THE CATEGORIES AND READ MORE

Innovative, compact and high quality developed central systems

Reduce your operating costs significantly, extend the life of your tools and protect the environment with a central filtration system from us.

CLICK ON THE CATEGORIES AND READ MORE

Wide range of high quality, compact and efficient lubricant filtering solutions

The well-designed filtration system will remove dirt and residue, and reduce your operating costs significantly. Extend the life of your tools and protect the environment now!

CLICK ON THE CATEGORIES AND READ MORE

Additional powerful and compact filtering accessories

Filco industry machine connections are the most gentle to fluids on the market.

CLICK ON THE CATEGORIES AND READ MORE

Machine connection

The machine connections are designed for our central filtration systems but can easily be implemented for similar systems from other manufactures.

Return stations are an essential part of the centralized filtration system, because why invest in a world class filtration system if your machine connection is not managing to transport all contaminants polluting the process fluid to the filtration system?

It is very important to consider the type of machine connection when installing a filtration system. The right machine connection is just as important as the filtration system itself, and the installation must be carried out by trained personnel to avoid issues with the efficiency.

Our technical specialists determines in dialog with the customer which solution is most suitable depending on several factors such as contamination level, pump pressure, volume and space.

We manufacture and install two types of machine connections, which is used depending on customer application and economy.

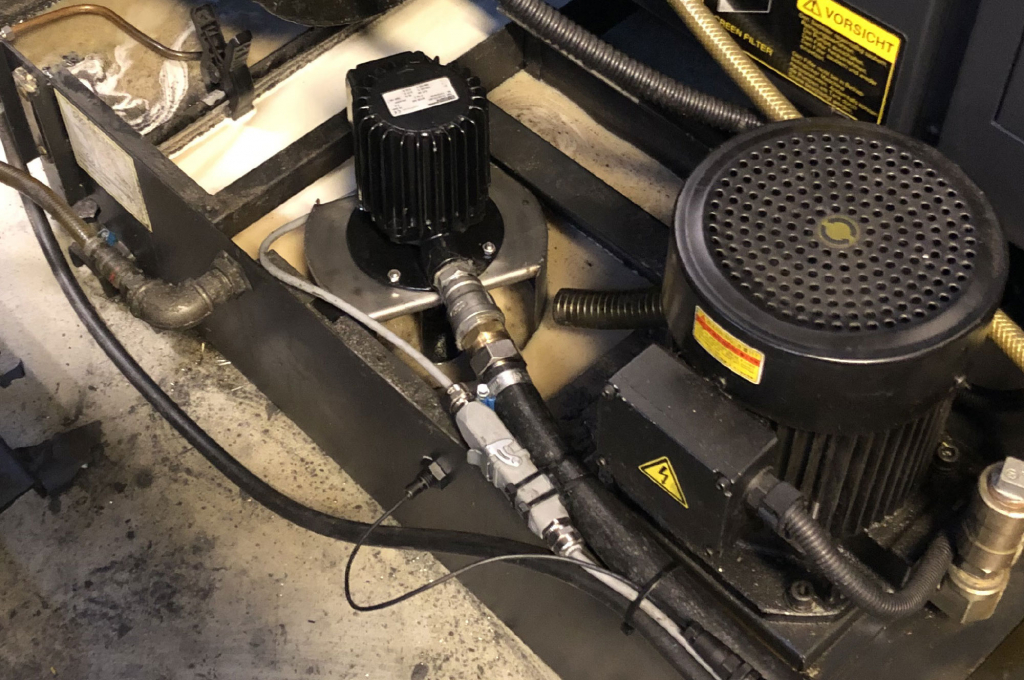

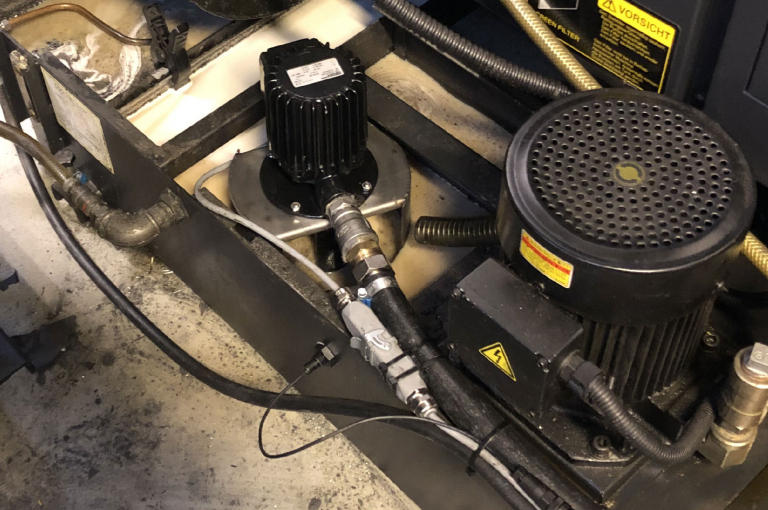

The first type is our high-end external connection type CA with frequency-regulated pump, stainless steel self-cleaning Ø400 return vessel and capacitive level sensor. Our self-cleaning round pump vessel type CA with conical bottom avoids the accumulation of particles. The pump completely empties the entire vessel, making cleaning unnecessary. The design of the pump allows larger particles to pass through, making it suitable for machining processes.

The second type is our less expensive integrated connection type DIR, where the Ø200 pump vessel is placed directly inside the machine.

FEATURES

Easy-to-install

Our machine connections are designed to be implemented almost anywhere.

Universal solution

The machine connections are designed to handle metal- and plastic chips, particles, general soiling, oil etc.

Leading experts

Our highly skilled professionals will assist you with installation or carry it out on-site according to your wishes.

Flow control

We assist you with determining the right flow and adjust the connection to your application.

TECHNICAL DATA

MACHINE CONNECTION CA | MACHINE CONNECTION DIR |

|---|---|

|

|