Innovative stainless steel machines for most efficient oil seperation

The innovative oil separator is made of stainless steel and includes a four-chamber labyrinth system, which efficiently enables the separation of oils.

CLICK ON THE CATEGORIES AND READ MORE

Compact, powerfull and effective magnetic solution

Easy to integrate into existing equipment and is mainly used for mounting on a band filter. This magnetic separator comes with a very powerful magnet and a large surface area, which makes it extremely effective in removing magnetic particles.

CLICK ON THE CATEGORIES AND READ MORE

Innovative, compact and high quality developed central systems

Reduce your operating costs significantly, extend the life of your tools and protect the environment with a central filtration system from us.

CLICK ON THE CATEGORIES AND READ MORE

Wide range of high quality, compact and efficient lubricant filtering solutions

The well-designed filtration system will remove dirt and residue, and reduce your operating costs significantly. Extend the life of your tools and protect the environment now!

CLICK ON THE CATEGORIES AND READ MORE

Additional powerful and compact filtering accessories

Filco industry machine connections are the most gentle to fluids on the market.

CLICK ON THE CATEGORIES AND READ MORE

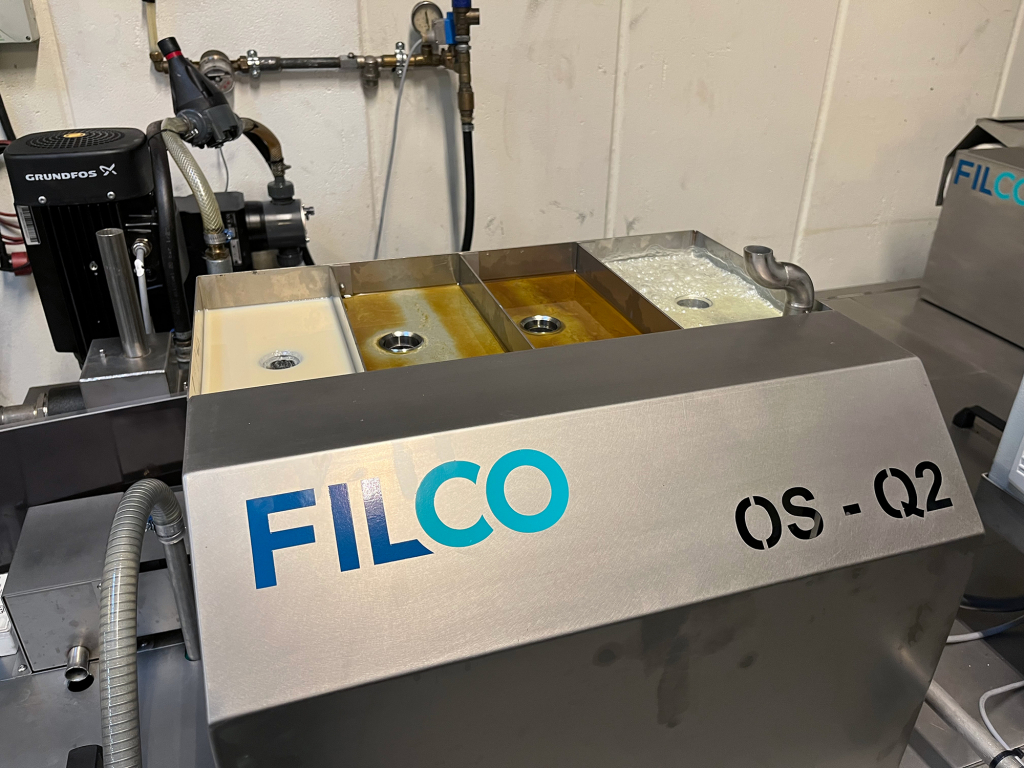

Oil separator

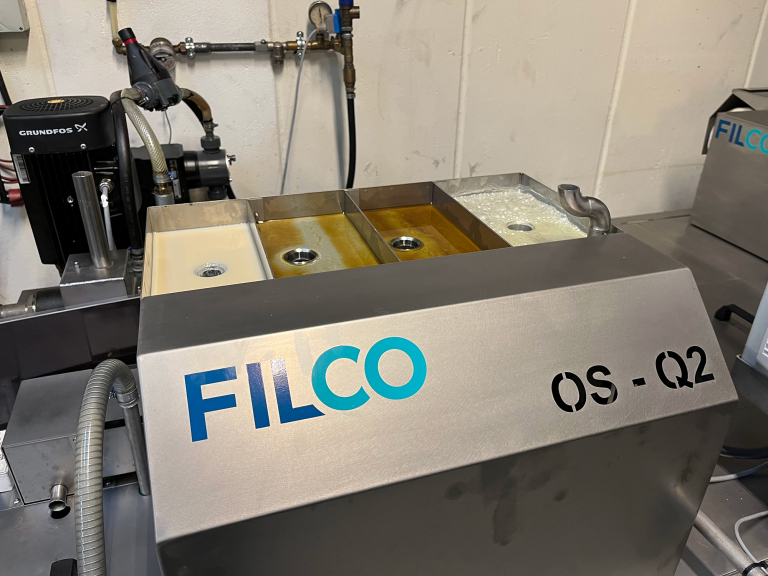

Innovative high-quality oil separator constructed in stainless steel

The oil separator is designed with a two or four-chamber labyrinth system which ensures efficient separation.

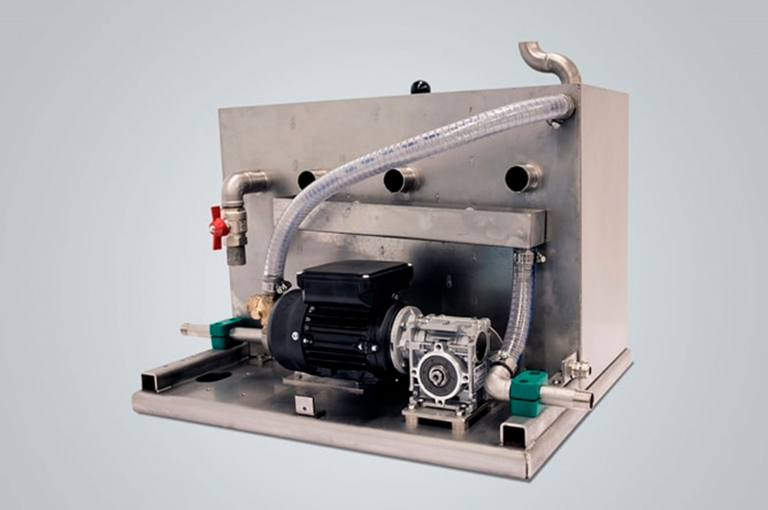

The surface oils are sucked into the oil separator by means of a self-levelling suction head. This is placed in the tank where the unwanted oils are to be removed from. The labyrinth system ensures optimal conditions for separation of the fluids. Due to our in-house developed piston pump further mixture of the fluids is prevented as the pump handles the fluid very gently. The oil separator ensures that the process fluid is always free of unwanted oils, which effects operation and process fluid lifespan.

Applications:

- Tank units from washing systems

- Machining centers

- Process fluid tanks

- Waste water treatment

FEATURES

Continuous draining of surface oils

The oil separator ensures continuous draining of oils.

Flexible solution

Compact and flexible solution which can be used stationary and as a mobile unit.

Unique piston pump

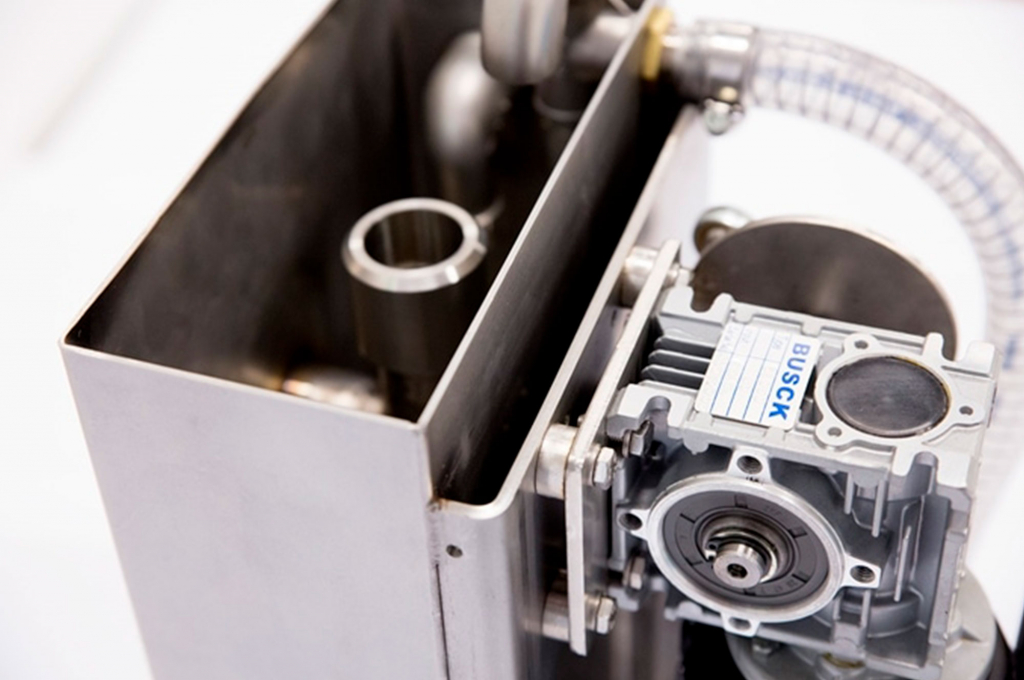

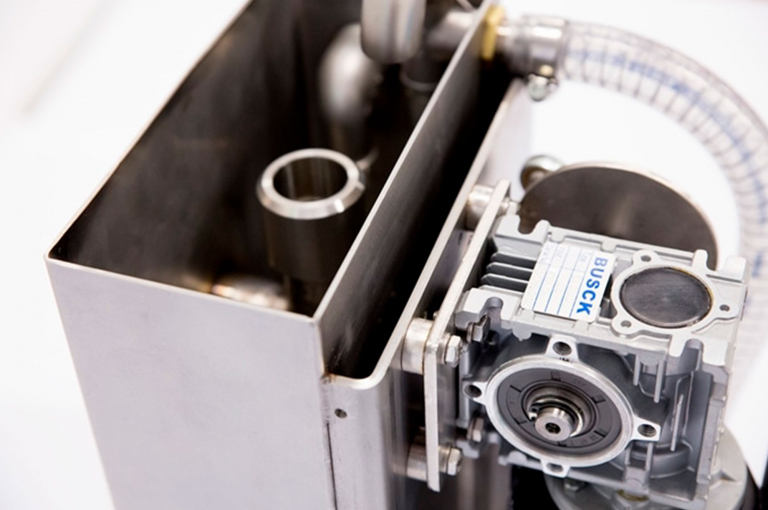

The in-house developed piston pump with stainless steel housing ensures efficient flow and gentle handling of the fluid.

Unique piston pump

The specially developed piston pump with stainless steel housing ensures efficient flow.

Suction head included

The oil separator includes a suction head ready for installation into tank units. The suction head floats at the surface where it creates suction that causes a natural flow to the suction head.

Chamber system

The oil separator has either a two or a four-chamber labyrinth system, which ensures efficient separation of oils.

Extends the lifespan of process fluids

Efficient separation of oils extends the lifespan of the process fluids and lowers costs.

100% stainless steel construction

Produced in AISI 304 / EN 1.4301.

CE – EU Machinery Directive

The oil separator is produced in Denmark in conformity with the EU Machinery Directive.

TECHNICAL DATA

| Model | OS-S2 | OS-Q2 |

|---|---|---|

| Flow capacity | 120 l/hour | 120 l/hour |

| Separation chambers | 2 | 4 |

| Electrical connection | 1x230V / 3x400V + PE 50 Hz | 1x230V / 3x400V + PE 50 Hz |

| Length | 305 mm | 500 mm |

| Width | 260 mm | 600 mm |

| Height | 400 mm | 470 mm |

| Weight | 7 kg | 20 kg |